Research & Development

Diamond Ceramics dedicate on R&D since the beginning of the company, a leading innovation team has been nurtured, which mastered the industry source technology and created a solid foundation for the company’s continuous innovation and sustainable development. 51 patents on engineering, equipment and technology are approved and more in processing. Diamond Ceramics were awarded for outstanding achievements both in the state and the nation.

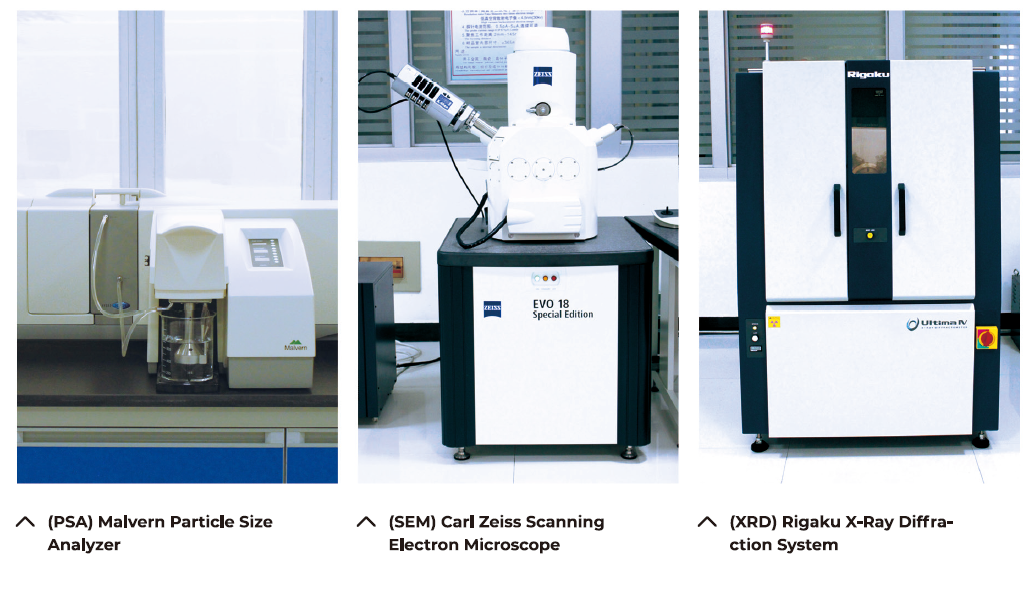

Diamond Ceramics Lab is equipped with cutting-edge equipment for formulation, testing, quality control and research, and qualified as the only Ceramic Materials Engineering Laboratory in the state. Diamond Ceramics co-operated with the State Environmental Protection Department to form the Technology and Research center that devote into green earth projects. The Lab is also established as the standard third party lab for national oil companies.

The flagship lab was well equipped with top analytical and testing equipment from USA, Japan and Germany.

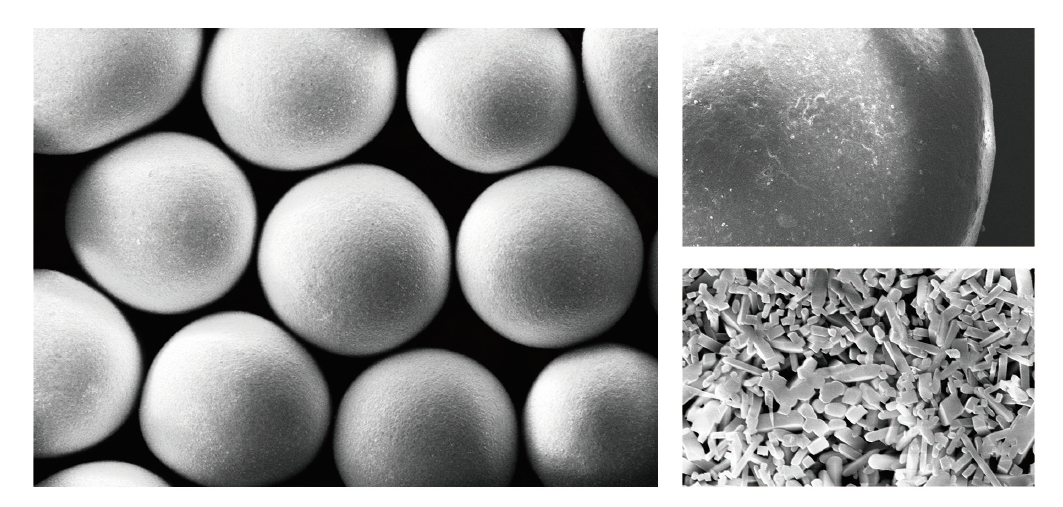

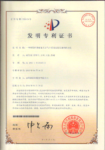

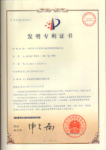

Diamond Ceramics’R&D strengths and expertise endow Diamond series products outperform others in industry. The smoother surface and higher roundness/sphericity contributed from the special waterfog process further reduces the tortuosity of proppant pack, which dramatically improves the conductivity and permeablity. The enforced sintering process generate more cross linked mu I lite to provide the best strength for proppant.